Bimetal Contacts & Trimetal Contacts ----- Unique Beating Techonlogy of Rivets Contacts

- Share

- publisher

- LML

- Issue Time

- Jun 1,2022

Summary

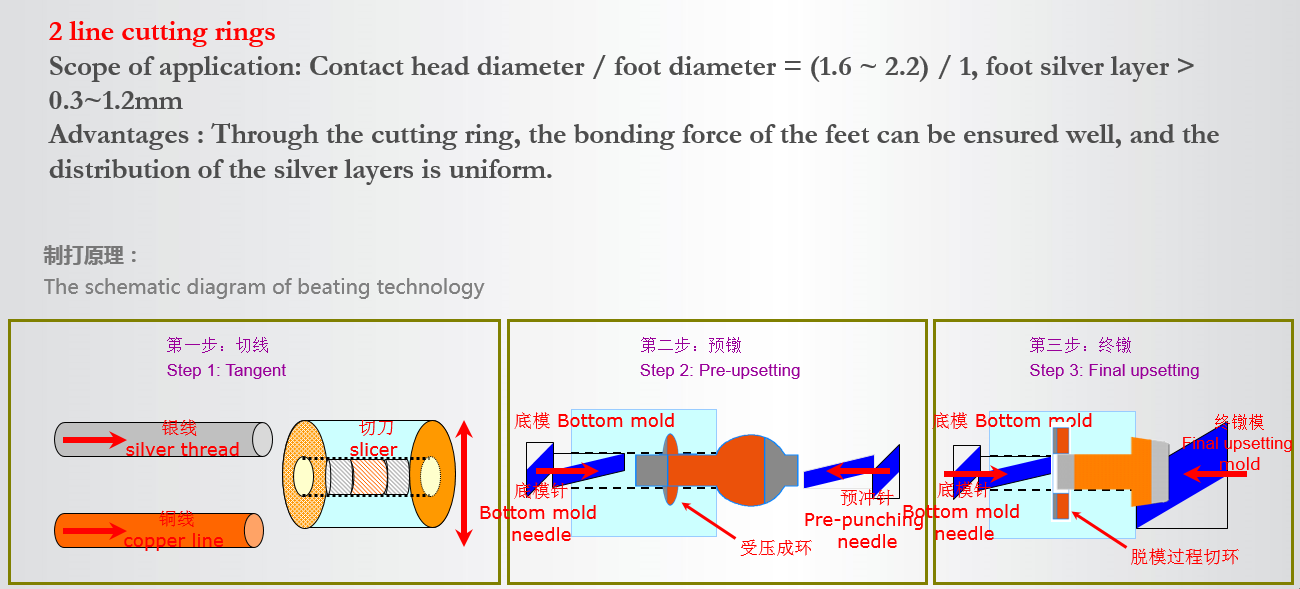

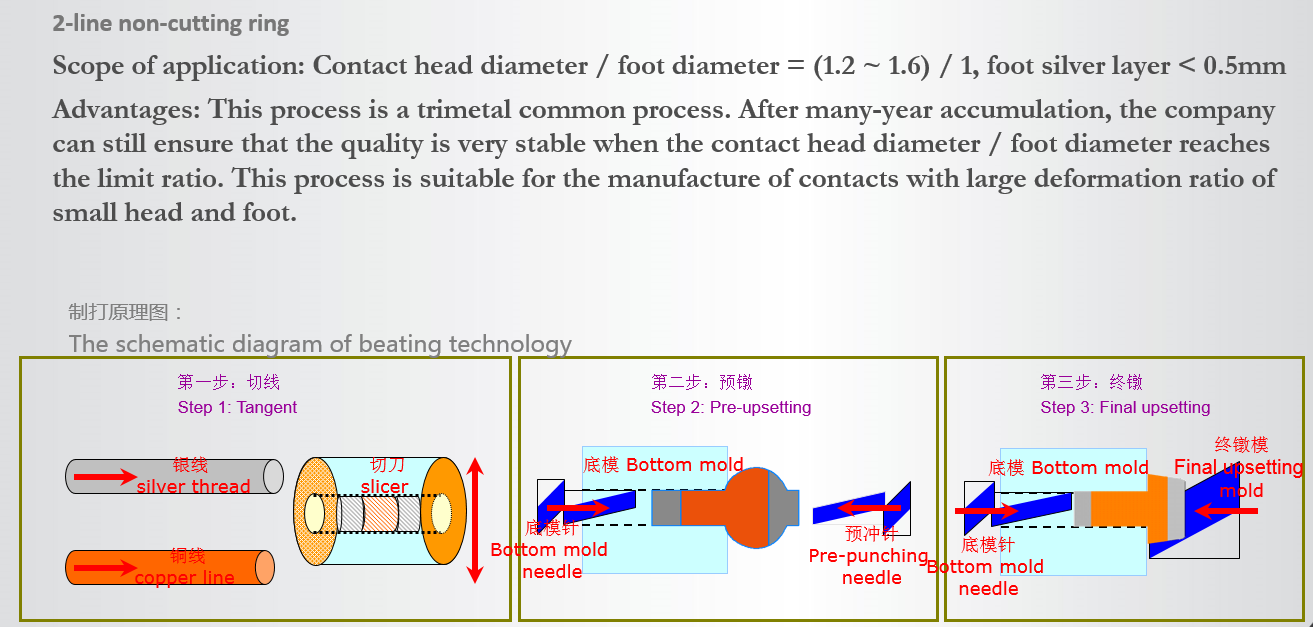

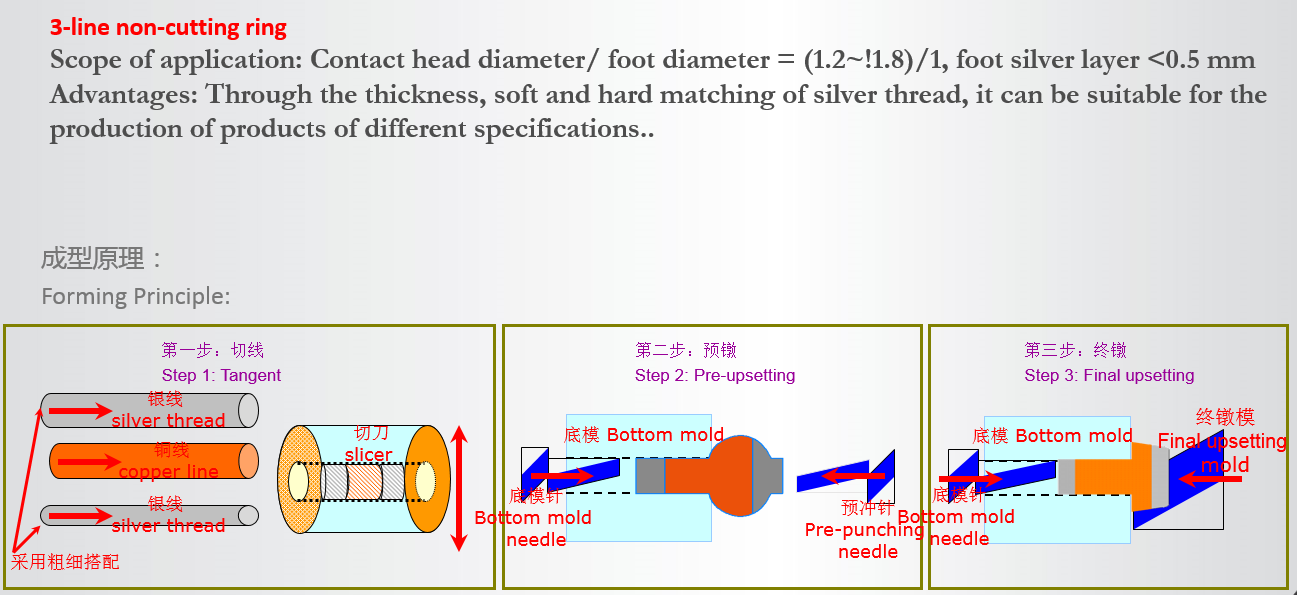

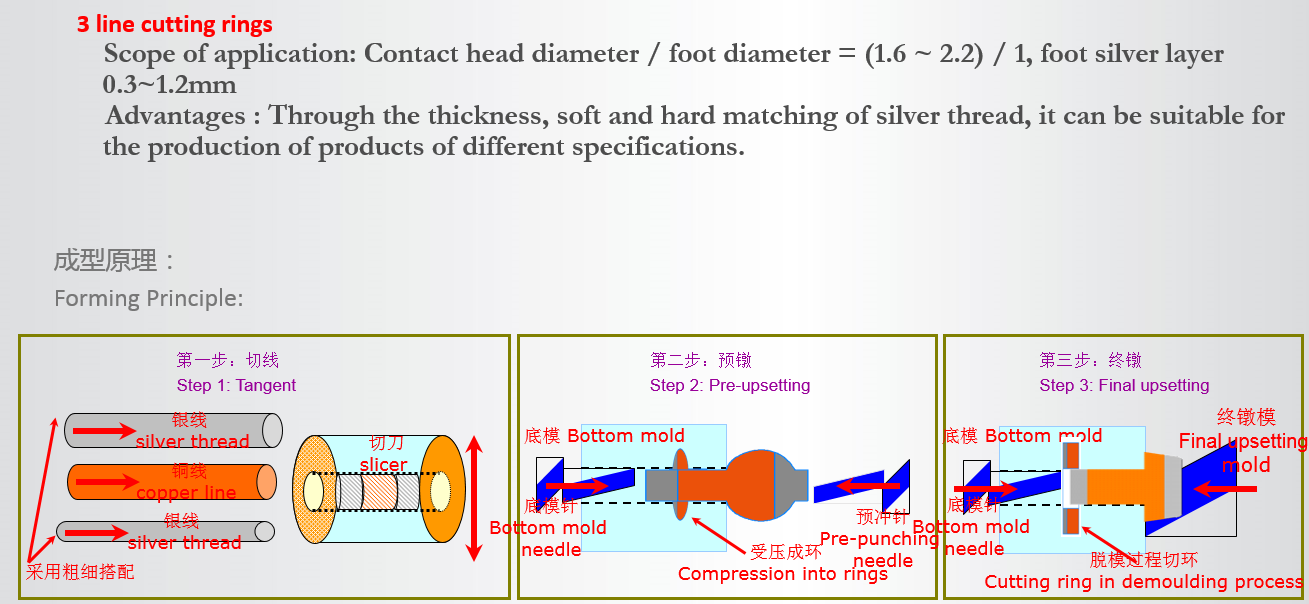

There are 120 riveting machines. Based on the cooperation between the company and domestic rivet machine manufacturers, LML independently develops, designs and improves them, which is at the leading level in China. At the same time, it is equipped with mold design and processing workshops, which can meet the production and processing requirements of products of different materials and specifications. The monthly production capacity of rivets reaches 100million.

Why should we choose the composite contact rivet instead of solid contact?

The overall copper contact has low acid-base resistance and oxidation resistance, so the copper silver plating can improve the contact quality without increasing the cost too much; The whole silver (silver alloy) contact has good burn resistance and fusion welding resistance, low contact resistance and stable temperature rise. It is the first choice for medium and high-end contacts, but the cost is high, which is not conducive to saving resources.

The contact is based on copper and silver is composite , which can greatly save the cost (compared with the overall contact, it can save 50-75% of the silver alloy), save precious metal resources, which is also a revolution in the contact industry. Bimetal and trimetal rivets are widely used in AC contactor auxiliary contacts, relays, switches, household appliances, timers and other low-voltage appliances.