Detailed Description to the Processing Process of Contacts Materials ---- Professional Technology

- Share

- Issue Time

- Jun 13,2022

Detailed Description to the Processing Process of Contacts Materials

High voltage contacts can be made into different shapes by powder metallurgy (extrusion / sintering / infiltration).

From the raw material to the silver alloy electrical contact material, from the contact, the composite strip, the component production to the pre-sales after-sale service. The Huano alloy has the ability to control the whole process of production and quality. In order to ensure the stability of the product quality, the key quality control points are controlled by the Huano alloy by means of various techniques and analytical tools.

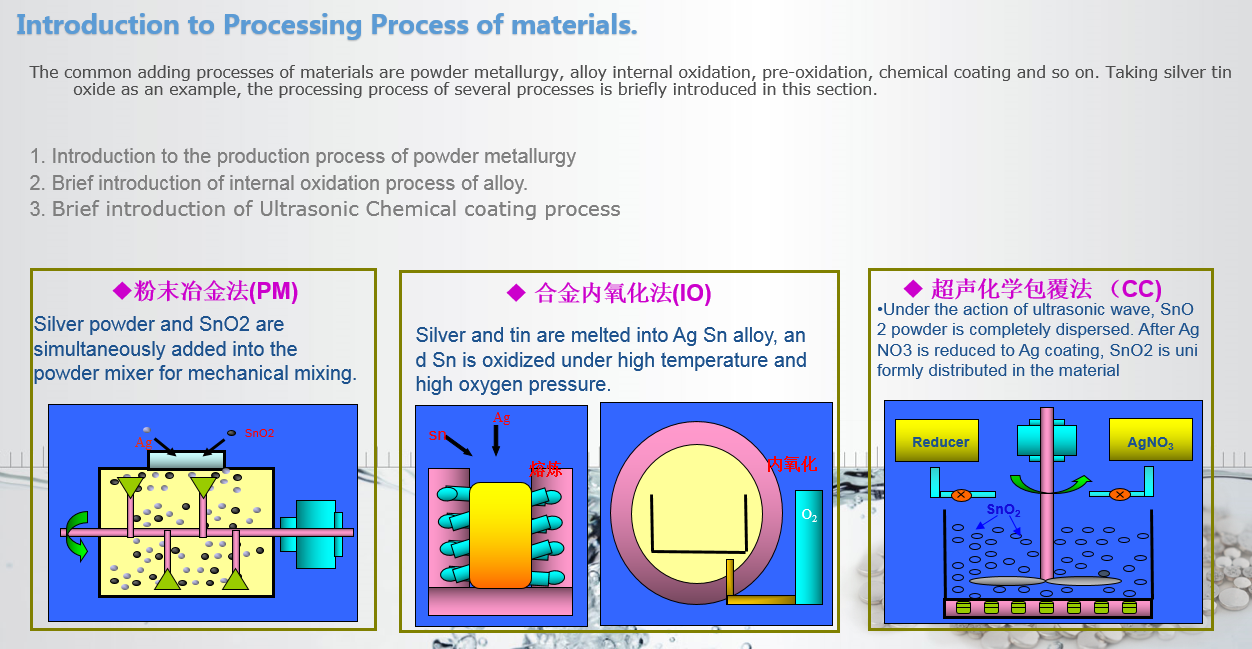

Taking silver tin oxide as an example, the processing process of several processes is briefly introduced in this section.

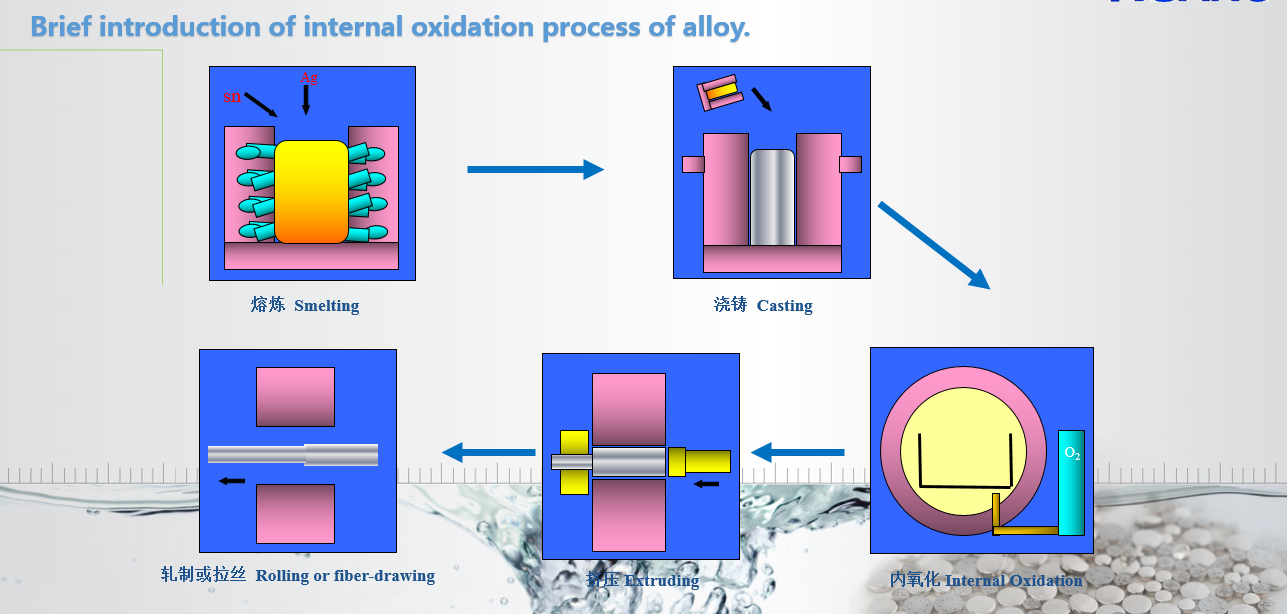

Internal Oxidation Alloy

Characteristics

ØDuring internal oxidation, Sn is

difficult to oxidize completely

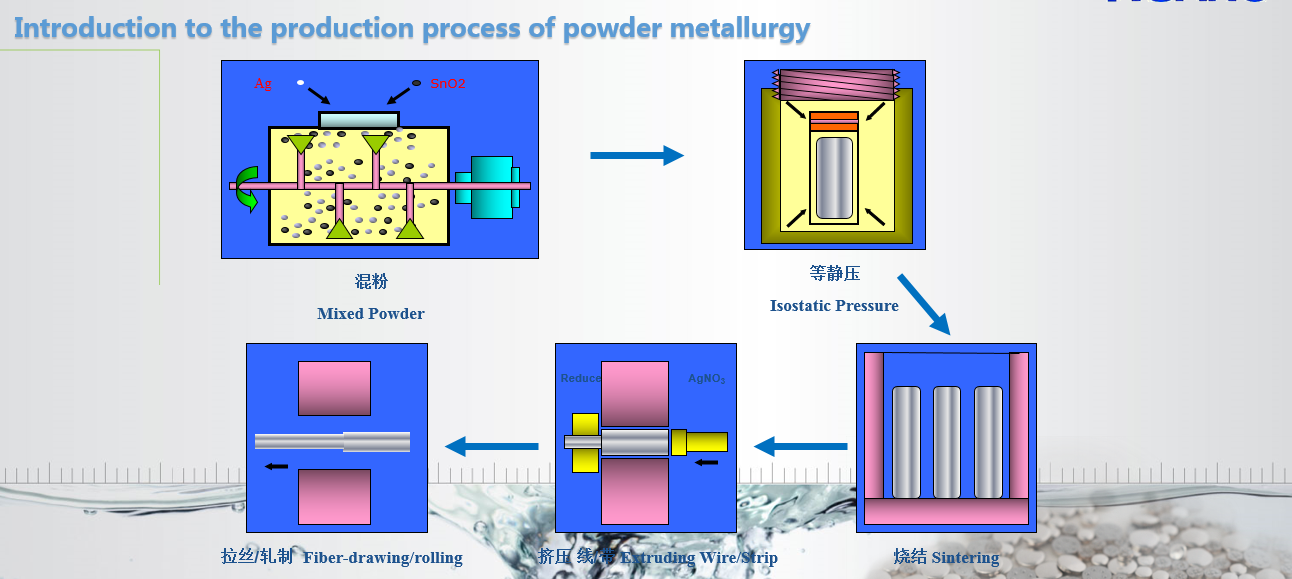

Powder Metallurgy

Characteristics

ØUneven distribution of SnO2 powder;

Ø Poor combination strength of Ag and SnO2, poor processing performance of materials;

ØThe density and resistance of the material can not reach the technological standard of internal oxidation of the alloy.

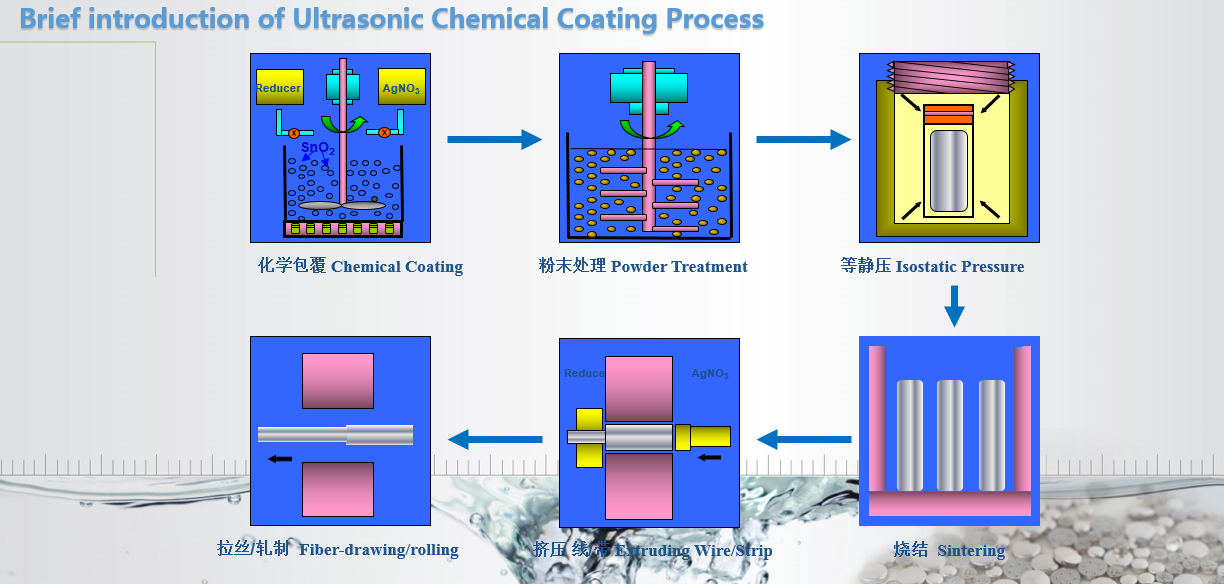

Ultrasonic

Chemical Coating

Characteristics

ØThe SnO2 powder is uniformly

distributed;

ØThere

is no incomplete oxidation of Sn in direct use of SnO2.

ØThe

bonding strength between Ag and SnO2 is good, and the processing performance of

the material is improved effectively;

ØThe

density and resistance of the material are the process reference for oxidation

method in the alloy.